To understand what I did and how I did it, we need to rewind a couple of years to first grasp WHY I chose to do this DIY Electric Jeep Hardtop Hoist. I am going to take you back to 2019, just after I bought my very first Jeep, what we now know as the Road Rash Off Road rig.

When I bought my Jeep, I had a specific list of things I wanted on it. One of these things I was adamant about including was a hardtop that I can have installed on the Jeep during the winter months for extra warmth and sound proofing. I didn’t even think about how I was going to take it off or where I would store this top. In addition, I live in a smaller townhome, traditionally not the type of garage that is set up for a large amount of storage. So it was time to research and get to work.

I needed this Electric Jeep Hardtop Hoist to solve many issues so I began making a list of requirements for this project. Because I traveled often for work, I needed this hoist to be easy for my wife to remove the top by herself. My wife is a smaller woman without the capacity of lifting a big, bulky 150 lb fiberglass top. I needed it to be safe and secure so it wasn’t swaying all over the place. I needed it to be cost effective and I finally I needed it to easily store out of the way because my garage is small and doesn’t have a lot of available room to stash a hardtop. That meant this top needed to be stored high on the ceiling for space and needed to be electronic for ease of use and weight.

After hitting the internet and searching several YouTube vlogs, I came across what seemed to be a couple of perfect options. One YouTuber, Greg Wessels posted a video showing a “concealed Jeep hardtop hoist“. This gave me a great idea to start putting together sketches and preplanning for converting my garage into the perfect Jeep storage hoist.

Let’s plan out our Hardtop hoist design

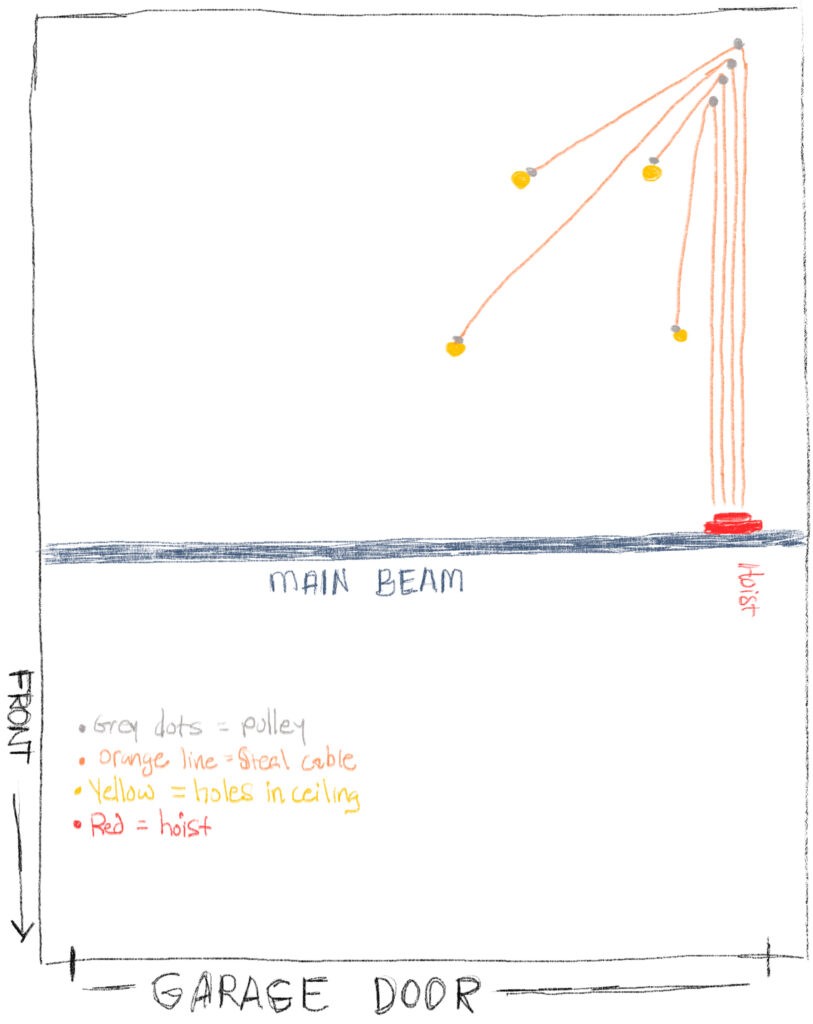

First up, measuring and sketching the layout of my garage attic space, making sure I had enough open room to run the designed winch and pulley system.

The idea is to bolt an inexpensive winch to the main beam in the attic and run 4 steal cables from the winch to an adjacent pulley board, with the pulleys set at a resending distance so that the steal cables do not cross over and touch. Each steal cable is pulled to the 4 corners of the hard top location below. I would cut a 3″ diameter hole into the ceiling above the 4 corners of the hardtop and fix a small cross beam over each hole across the top of the ceiling joist. On that cross beam, I would screw another pulley that redirected the steal cable down, through the holes and into the garage.

Now we have a sketch and accurate measurements, let’s put together a list of items we need.

What I need to build this Electric Jeep Hardtop Hoist

First and foremost, we need a winch strong enough to securely hold about 150 lbs. I found many used options on Facebook Marketplace for under $60. These were traditionally older ATV winches that would have defiantly done the job but ultimately I ended up going with a bran-new lightweight winch from Amazon that would be more than sufficient. This remote control winch already came with a 110v plug and could lift 440 lbs. (You can find this here)

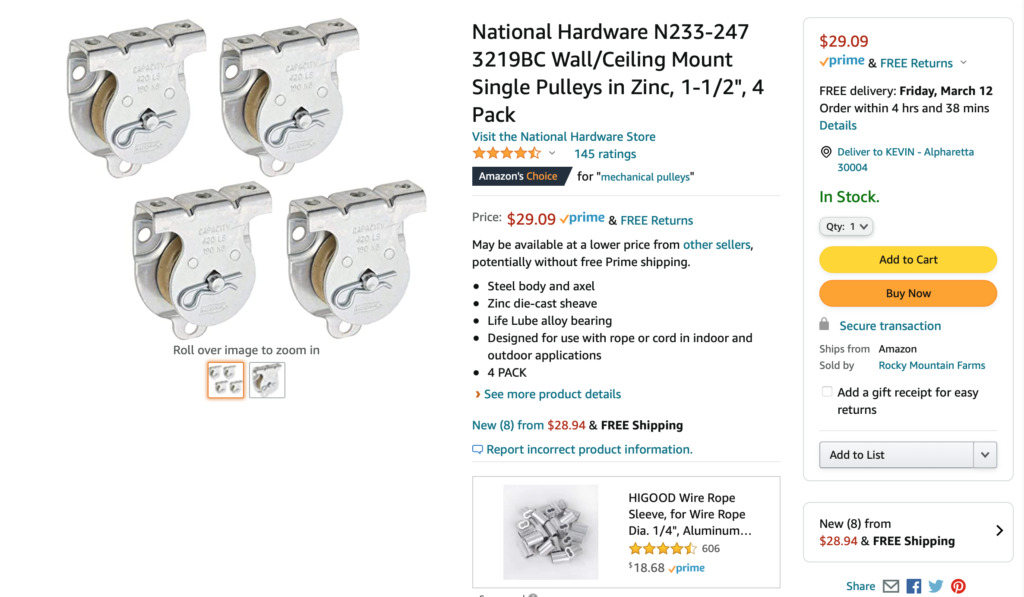

Next I found a pack of 4 single pulleys. I ordered 2 packs of these as I actually needed a total of 8 pulleys (you’ll see in the construction part).

These were great pulleys because they had 2 different mounting options. Either they could be screwed from the top or they could be screwed from the side.

Next, I needed some steal cable (enough to run the distance from the winch, through the adjacent pulley system and to the corner of the hard top – 4 separate lines). I also needed 2 durable tow straps at least 5 feet long. These will go from the front of the hard top (near the back passenger door) to the rear of the top at the back window.

Finally, we needed some D-Rings to clamp onto the steal cable that will attach the tow straps. You can see the ones I bought here

Now it’s time to get physical!!! I backed the Jeep into the garage and positioned it where I normally park it. I measured the exact distance from the back wall and from the drivers side wall to the 4 corners of my hardtop. This allowed me to mark the exact position that the steal lines will need to come down from the ceiling to grab my hardtop. I cut 4, 3″ holes into the ceiling at the hardtop corner locations. Now, I can jump up in the attic and begin the install.

After bolting the hoist to the main beam as close to the wall as I could, I installed the simple cross beams with the “down pulley” positioned over each of the 3″ holes. I roughly laid out all of my steal cables in a way so that I can cut each to it’s respective length and confirm they do not touch each other. YOU DO NOT WANT THESE CABLES TOUCHING AS IT WILL BEGIN TO WEAR OVERTIME AND WILL EVENTUALLY BREAK. After roughly laying out the steal cables, I was able to crawl back to the “pulley board” and position the resending pulleys accurately, screwing them to a secured 3/4 sheet of plywood.

I drilled a small, 5th hole in the ceiling near the Hoist itself and dropped the wired controller down to operate it. Finally, I attached the D-Rings to the end of each steal cable and slipped on the tow straps. Now it’s ready for testing. As I began to let down the straps, I noticed the D-Rings I selected did not weigh enough to keep tension on the steal cables (you can probably find a heavier D-Ring). So you will notice I added a couple of links from a steal chain to my D-Rings, just enough to pull tension on my cables as the hoist was released.

The straps lined up perfect. With the back window open and the back doors of the Jeep open, I ran the tow straps through the back window and along the inside of the hardtop (outside of the roll bar). Then, I brought the tow straps out of the back door and attached it to the D-Rings on the front cables. Before lifting the top, I checked to make sure all plugs from the hardtop to the Jeep were disconnected and all screws to hold the hardtop on the Jeep were unscrewed. You can easily double check this by lifting the hoist very very slowly at first, peeking inside of the Jeep to make sure the top is moving freely. If it is not, STOP LIFTING and walk around the Jeep to double check. The top should lift very easily with no resistance.

That is it. If you have any questions, feel free to shoot me an email. I don’t mind answering the best I can and if this DIY Electric Jeep Hardtop Hoist worked well for you, please share this post and my YouTube video with your friends. Check back for my other Jeep DIY and adventure blogs including soft top options, rooftop lights and door storage.